Compound Die Stamping Services

If you choose the right production method, complex steel parts can be cheap to make. Compound die stamping produces steel parts swiftly, efficiently, and correctly every time. RICKOTEK provides compound die stamping services to a wide range of customers.

How Compound Die Stamping Works

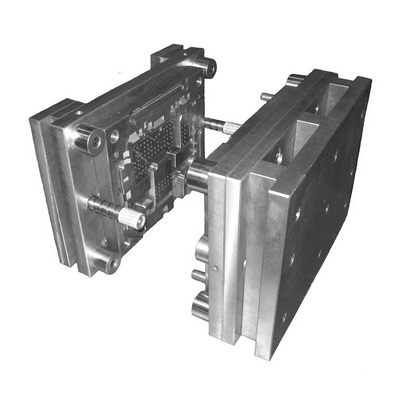

The compound die stamping system feeds a strip of steel through the compound die, which punches out a part in a single stroke. The system continues to feed the steel strip through the die until all the pieces have been punched out.

It’s a cost-effective way to produce medium to high volume metal stamping parts, and also helps keep the labor cost and dies cost down using the compound die stamping process.

Advantages of Compound Die Stamping

- Speed: Compound die stamping can produce a part every 3 seconds, or 1200 pieces per hour.

- Efficiency: Compound dies can cut complex parts all in one stroke, eliminating the need for multiple dies.

- Repeatability: By creating parts with one die, we’re able to ensure consistency.

- Cost-effectiveness: Because compound dies can produce your part quickly and effortlessly, you can expect to save money.