Deep drawing is when metal sheets under high compressive and tensile forces are drawn into a die cavity forming an irregular cup shape.

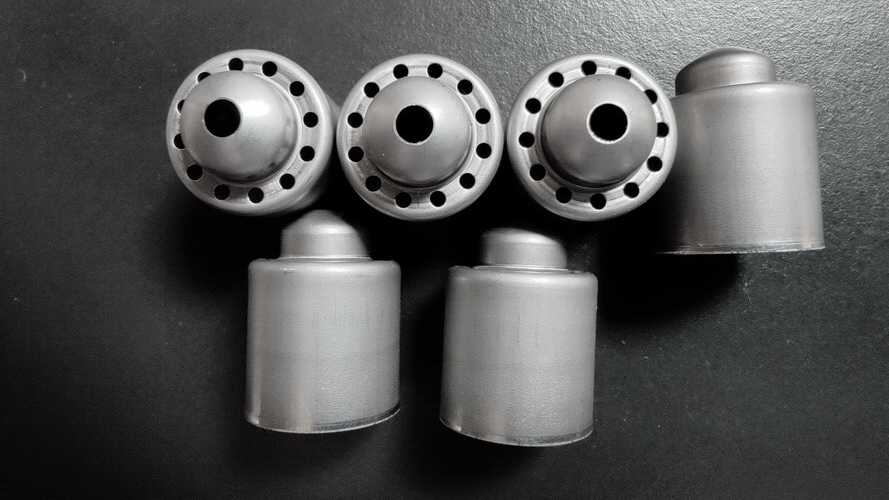

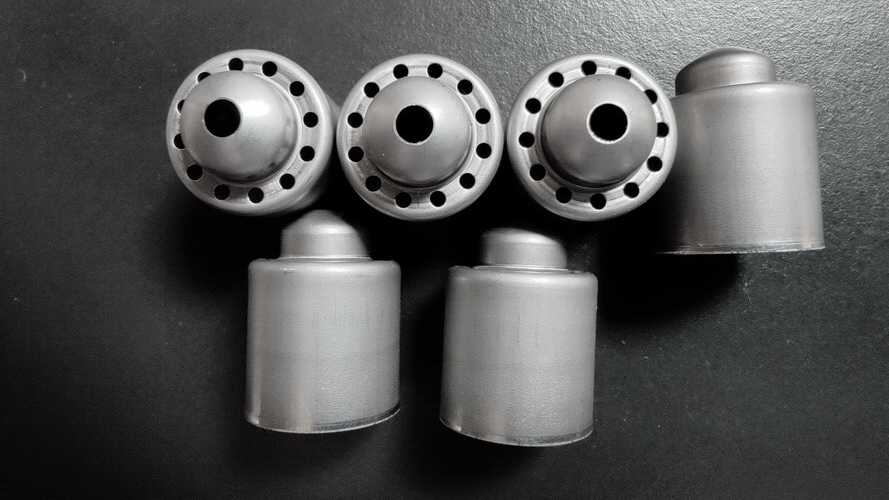

Metal sheets are formed using deep draw stamping to create different types of hollow axisymmetric parts. The deep-drawn stamping services offer mostly cylindrical shapes, but they can produce box-shaped components as well.

Additionally, it is widely used in forming various industrial and household objects, including baking pans, sinks, automotive parts, plumbing fixtures, casings, beverage cans, and many other components.

With this type of metal drawing process, the presses apply a punching motion to the metal sheet forcing it into the die cavity, The process begins by placing a metal sheet on the forming die.

The compressive force of the press is applied at both ends with a blank holder of the sheet. Meanwhile, the sheet has an axial force applied using a mechanical punch tool, forcing the piece to deform while flowing into the die cavity and making the shape desired.

The term “deep drawn stamping” received the name due to the last component, typically having a larger ratio of depths to diameters.

The deep drawing process is widely used in many industries, including Automotive, Aerospace, household appliances, Plumbing, Lighting, electronics, etc.

We have provided various manufacturers with custom deep-drawn stamping services to produce components and parts for the medical, automotive, consumer goods, alternative energy, and aerospace industries.

With a fleet that includes more than twenty 250-ton presses that offer a broad range of press strokes and 4 hydraulic deep drawing machines, We can produce very deep drawn parts and significant stamped components.

We can offer you different customized die sizes, up to a maximum of 4ft in width, and 8 ft in length, for a range of materials, including:

| 1. Plastics | 2. Aluminum | 3. Brass | 4. Copper | 5. Nickel | 6. Steel |

|---|

The components we produce in our facilities average a thickness of 0.005 and 0.5 inches. Furthermore, we have tight tolerances during the manufacturing process.

Our facility ensures all of the deep-drawn stamping services, assemblies, and sub-assemblies are manufactured with our strict quality control standards and ISO 9001:2015 & IATF 16949:2016 certified processes each step.

We use inspection systems, including coordinate-measuring machines (CMM), camera vision equipment, and various control and monitoring systems to ensure we always meet the client’s requirements and comply with industry standards while maintaining tolerances.

One key benefit includes the high-quality characteristics of the final components, that is creating a final product without joined parts or seams using a single piece of metal.

Therefore, reducing the potential for weak points reduces the chance of leaks or failure, which products with seams are susceptible to.

Besides, the deep-drawn stamping process increases the strength of the material. A term referred to as ‘strain hardening.’

As the metal is deformed, the material’s crystalline structure is rearranged, causing the final product to become stronger.

The deep draw process offers advantages to higher production volume. After an appropriate die and tooling are created, the metal drawing process can produce thousands of high-quality parts through an automated process with repeatable accuracy.

It results in minimized downtime and cycles, keeping the unit cost down for every produced part.