The need for metal stamping manufacturers to create parts and products serves a broad range of industries, while many have associated metal stamping service for engine or construction parts.

The number of different fields in which this type of service is found is quite striking.

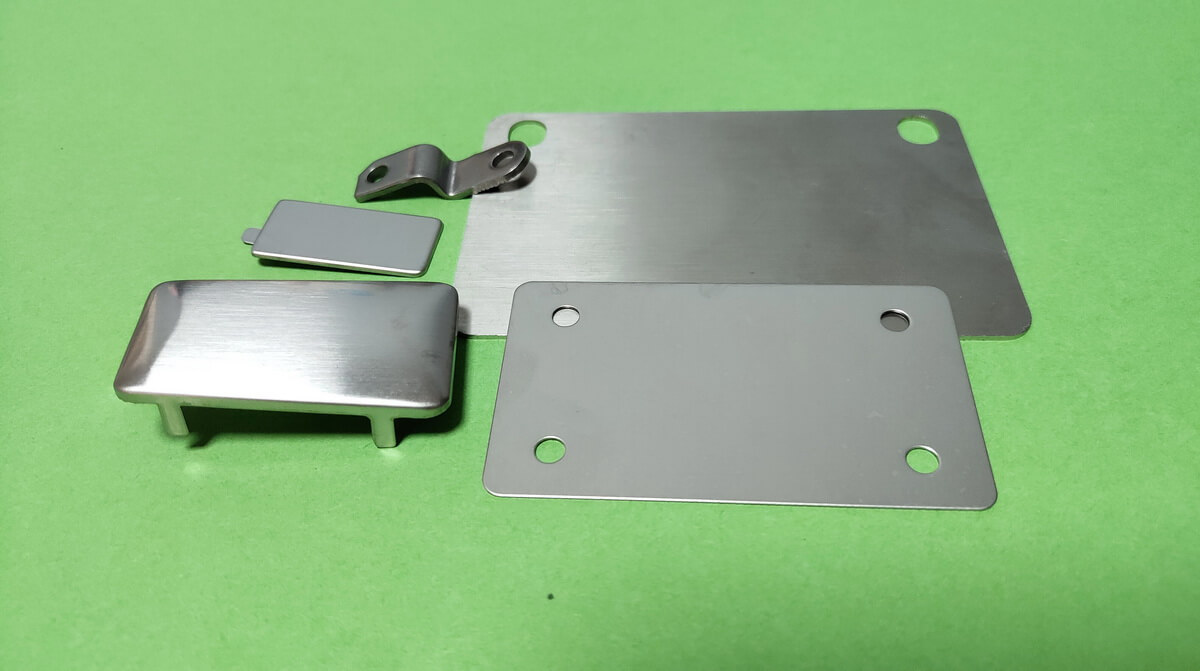

From creating standard parts to custom metal stamping to deep drawn stamping and more, you’ll find that such parts and products are used in a wide range of fields.

Metal stamping is a relatively simple process in which a sheet of metal is usually fed into a series of machines that bend, shape, and curve the material into a specific shape.

The automation of the process means that many types of parts can be mass-manufactured quickly. The result is that parts can be crafted from solid materials repeatedly as long as there are sheets of metal to feed into the machines.

What follows are just a few of the many different industries that rely on metal parts or products that are created using the metal stamping process.

Automotive

The many cylindrical and box-shaped parts created by deep drawn stamping are used in the automotive industry along with many other fields.

The many different automotive parts use this particular process for engines, car frames, and the like. Deep drawn stamping is used to create durable, long-lasting, and reliable pieces all from a single sheet of metal.

If you’ve taken a look in your kitchen, you will see examples of deep drawn metal stamping such as the aluminum bowls, pie pans, and other cooking ware that is crafted from metal.

This process allows for single metal sheets to be bent and curved in a manner that does not compromise their inherent strength or durability.

In the automotive industry, the most commonly used are mounts for the body and engine, but arguably the most frequently seen are exhaust mufflers.

The deep drawn stamping process also creates the many connectors and pins along with Jounce bumpers.

It’s difficult to imagine where the automotive industry would be today without this remarkable process.

Lighting

Of the many different applications for metal stamping, lighting may not come readily to mind.

Yet around the world, many types of lighting fixtures would be considerably different if it were not for this process.

While some do use custom metal stamping, many are the creation of parts that are relatively easy to recreate using this process.

Thanks to the development of the LED or Light Emitting Diode, the use of metal stamping as increased in some ways when it comes to different parts for lighting.

The most common types of parts used for lighting include, but are not limited to the following;

- Brackets

- Clips

- Covers

- Reflectors

- Shields

But that is only the beginning. Many of the wire forms, mounts, and springs that are commonly used in light fixtures for the ceiling and walls are also crafted using stamped metal parts.

You might say that from the power plant to the transformers to your home and to the electrical wiring that powers the lighting fixtures use in some form metal stamped parts.

Medical

You may not think of the medical field as being one that requires a metal stamping service.

But the truth is that this technology has made it possible for many different devices to be created. It is because the deep-drawn method allows for the creation of cylindrical metal parts that can be small, yet firm and durable.

Of the many different items created for the medical field using this process, some of the more prominent include the following;

- Dental Laser devices

- Devices to Deliver Insulin

- Pacemakers

- Syringes

- Temperature-sensing Covers for Probes

These are just a few types, but they represent the versatility of metal stamping. Especially in how it can be used to create many thousands of identical parts in a short period.

Solar Panels

Metal stamping manufacturers are a big part of the solar industry.

It is because the construction of solar panels requires uniform parts so that a single panel matches another.

Given that such panels are often joined by the dozens and assembled on-site, the uniformity that a metal stamping service provides is paramount to the mass production of panels.

The parts are not just the framing of the panels which is the most commonly seen products of metal stamping, but in many other parts as well;

- Bolts

- Clamps

- Clips

- Fasteners

Here, custom metal stamping is a must when new solar panel designs require unique pieces to be created. It includes the support structure for the solar panels once they are assembled and in-place.

The parts created to provide support must be able to withstand the elements and high winds. It is especially true for flat solar panels, which tend to catch the wind more than many other types of structures.

Besides, the racking and mounting of the panels will also consist of parts made by metal stamping processes such as brackets, flashing, panel clamps, and rails.

As more solar panels are created and the demand for this clean form of energy soars, so too will be the need for a metal stamping service to ensure such parts are readily available.

Conclusion

In all industries where a metal stamping service applies, the parts or products created must meet high standards in terms of strength, durability, and reliability.

While this depends in part on the metal used for their creation, it also means that the stamping process itself works with the metal to not create flaws or weak points.

From deep drawn stamping to custom metal stamping for specific parts and products, the metal stamping service can be found at the core of manufacturing.

Every day, you see products with parts that were created by metal stamping manufacturers and often in places that you do not expect. That is why metal stamping remains such an essential part of the manufacturing process.